// Our experience with buying and selling

You will be provided with professional advice and extensive knowledge throughout the entire process.

Value Trading has full control over all steps of the production process, including smelting,

taking samples, analysis, purification and final delivery of the final product.

Our belief is that we can always offer our customers the best conditions, service and most competitive prices on the market.

Below is an overview of our services.

// THE PROCESS

SMELTING

ANALYSIS

REFINING

TRADING

SMELTING

SMELTING

ANALYSIS

ANALYSIS

REFINING

REFINING

TRADING

TRADING

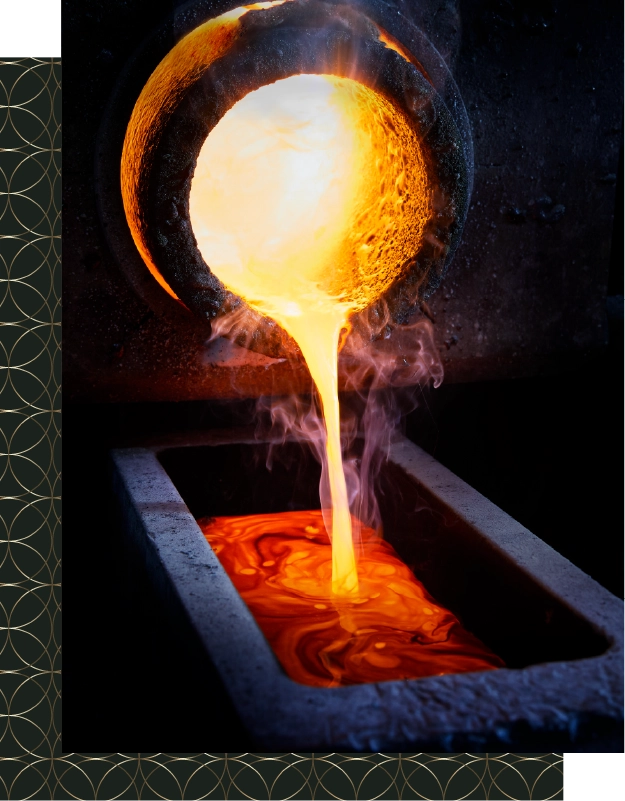

// SMELTING

Value Trading has access to a smelter equipped with 6 induction furnaces and produces 85 tons of pure gold annually. These furnaces have a melting capacity of up to 100 kg per melt, ensuring a rapid throughput of incoming lots.

In addition, Value Trading also has its own melting shop, where customers can safely watch during the sampling of their goods and the melting process.

// ANALYSIS

There are several ways to determine the content of gold, but the fastest and non-destructive method is by spectrometry. This uses X-ray beams to detect metals present in the sample. Within three minutes, the result is known. The device used is calibrated daily and undergoes multiple inspections by independent parties.

More accurate but destructive methods are also available, such as fire assay and ICP. These methods are performed by qualified assayer trained and approved by the Royal Mint of Belgium. The laboratory uses advanced weighing methods that are accurate to within 10 micrograms, guaranteeing very precise results.

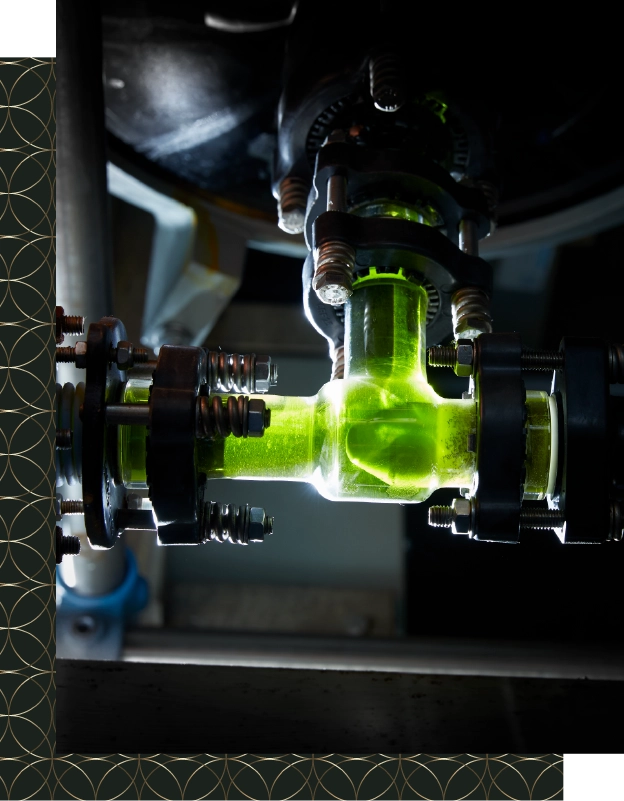

// REFINING

The purification of precious metals takes place in a modern refining department, which is fully controlled by a PLC system. Acids are dosed with great precision to cause the perfect chemical reaction, separating gold from other metals under the best conditions.

Applicable environmental standards are closely monitored and the safety of employees and work environment takes precedence. This is overseen in part by a safety & environmental coordinator.

// SMELTING

Value Trading has access to a smelter equipped with 6 induction furnaces and produces 85 tons of pure gold annually. These furnaces have a melting capacity of up to 100 kg per melt, ensuring a rapid throughput of incoming lots.

In addition, Value Trading also has its own melting shop, where customers can safely watch during the sampling of their goods and the melting process.

// ANALYSIS

There are several ways to determine the content of gold, but the fastest and non-destructive method is by spectrometry. This uses X-ray beams to detect metals present in the sample. Within three minutes, the result is known. The device used is calibrated daily and undergoes multiple inspections by independent parties.

More accurate but destructive methods are also available, such as fire assay and ICP. These methods are performed by qualified essayists trained and approved by the Royal Mint of Belgium. The laboratory uses advanced weighing methods that are accurate to within 10 micrograms, guaranteeing very precise results.

// REFINING

The purification of precious metals takes place in a modern refining department, which is fully controlled by a PLC system. Acids are dosed with great precision to cause the perfect chemical reaction, separating gold from other metals under the best conditions.

Applicable environmental standards are closely monitored and the safety of employees and work environment takes precedence. This is overseen in part by a safety & environmental coordinator.